Lightning protection systems (LPS) are critical for safeguarding buildings, equipment, and lives against the destructive effects of lightning strikes. One of the essential components of an LPS is the Test Link Box—a small but powerful tool that plays a major role in testing and maintaining the grounding or earthing part of the system.

In this blog, we’ll explore what a test link box is, why it is used, how it is installed, and how it contributes to the effectiveness of a lightning protection system.

How a Lightning Protection System (LPS) Works?

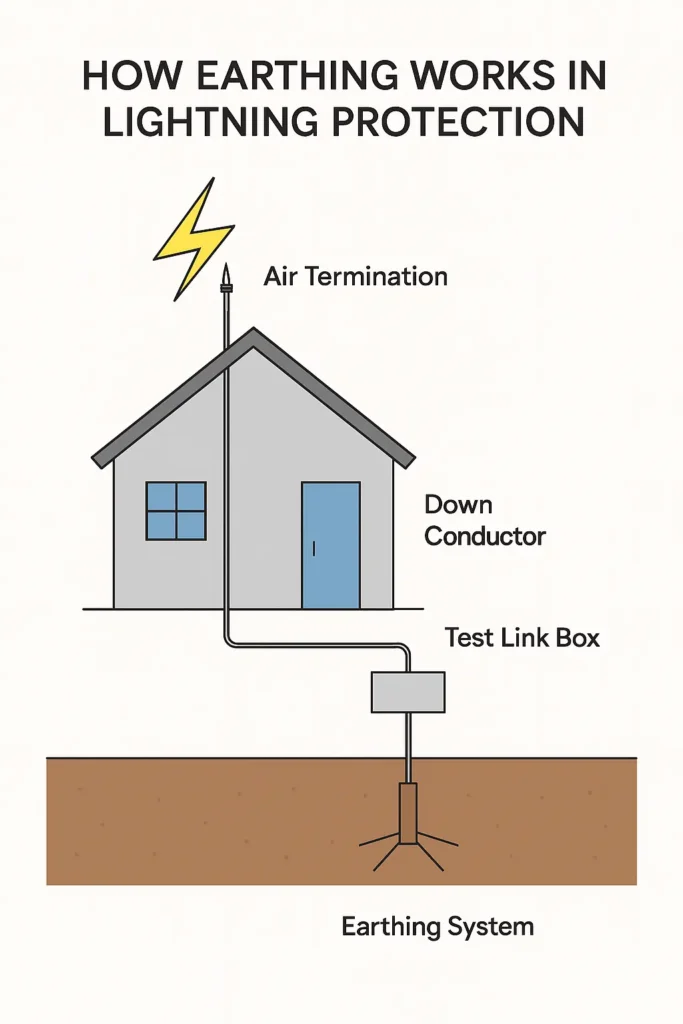

Before diving into the specifics of a test link box, it’s important to understand how a lightning protection system works. An LPS is a structured network of conductors, rods, and grounding elements that safely direct the high voltage of a lightning strike into the ground—preventing damage to the building, electrical systems, and people inside. The main parts of an Lightning Protection System are:

- Air termination system (lightning rods): The Air Termination System (lightning arrester) is the first line of defense in a lightning protection setup. It consists of metallic rods, meshes, or conductor networks installed at the highest points of a structure. These components are designed to intercept direct lightning strikes and safely conduct the high-voltage current toward the ground.

- Down conductors: Down Conductors are the metallic paths that connect the air termination system to the ground. Their role is to carry the intercepted lightning current from the top of the building down to the earth termination system with minimal resistance and without causing side flashes. These conductors are typically fixed along the external walls of the structure, maintaining safe distances from internal conductive parts and sensitive equipment.

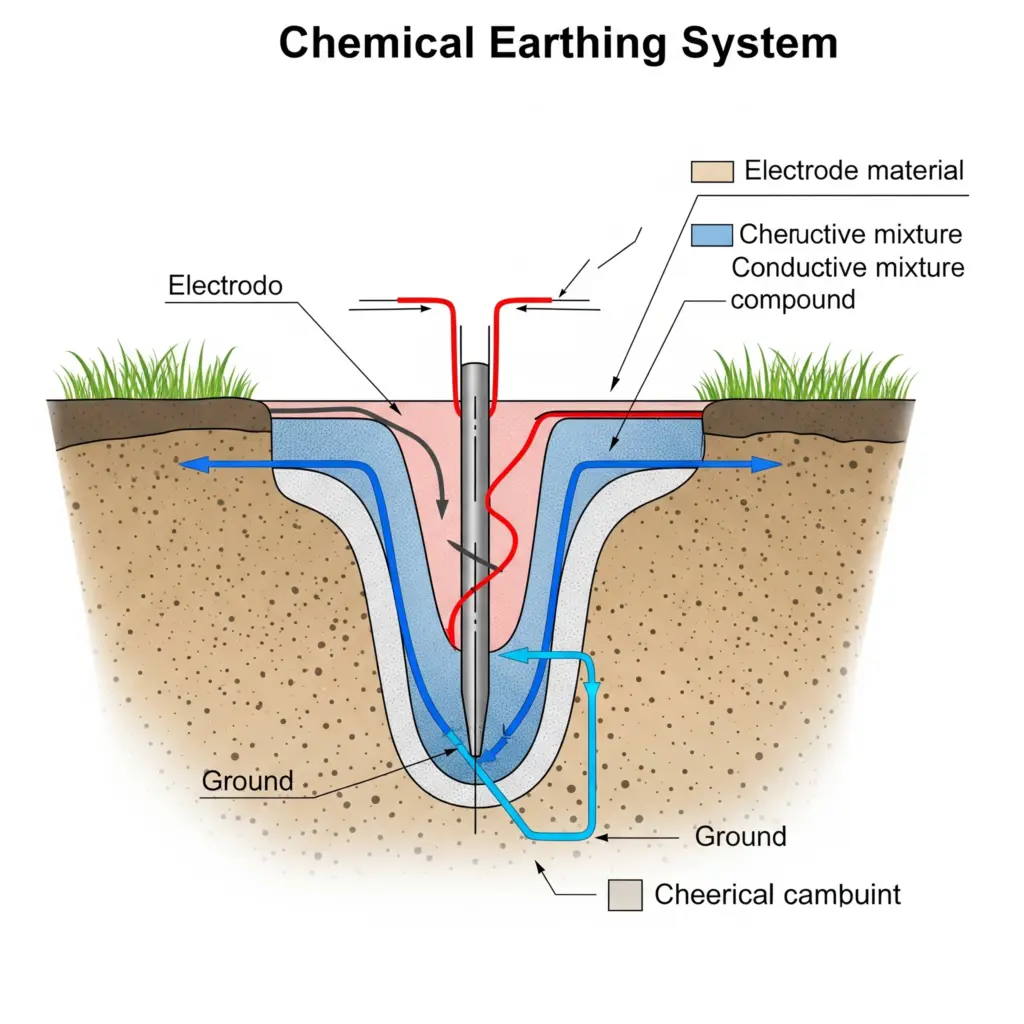

- Earth termination system (earthing): The Earth Termination System, commonly referred to as earthing, is responsible for safely dispersing the lightning current into the ground. This is achieved using earth electrodes like rods, plates, or rings embedded in the soil. A well-designed earthing system minimizes the ground resistance and ensures the electrical energy from the lightning is harmlessly discharged, protecting both the building and its occupants.

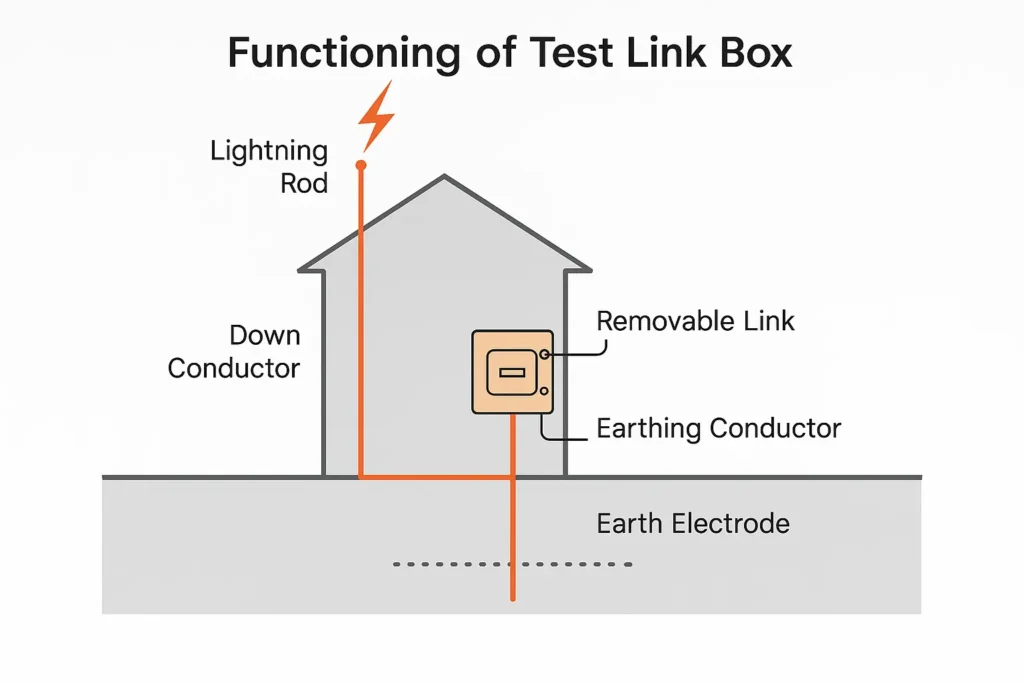

- Test link box: A Test Link Box is a crucial inspection and maintenance component of a lightning protection system. Installed at an accessible point between the down conductor and the earthing system, it allows for the disconnection of the earthing system to perform resistance testing and continuity checks. This ensures the lightning protection system remains functional and complies with safety standards through regular monitoring and maintenance.

Also, Checkout this detailed article on What Is Earthing in Lightning Protection?

What Is a Test Link Box?

A Test Link Box (also known as a test joint box or test clamp box) is an access point installed on the down conductor of a lightning protection system. It acts as an interface between the down conductor and the earth electrode (ground rod or earthing pit). Its primary purpose is to provide a safe, accessible location to disconnect and test the earth electrode system without disturbing the overall structure of the LPS. Here are the important features of a test link box:

- Typically made of weatherproof and corrosion-resistant materials (GI, copper, or stainless steel).

- Includes a removable or openable lid for easy access.

- Fitted with terminals or bus bars to connect the down conductor and earthing wire.

- Sometimes mounted inside a chamber for underground or outdoor installations.

Why Is a Test Link Box Important?

Even the most well-designed LPS can degrade over time due to corrosion, soil conditions, weather exposure, and mechanical damage. Regular inspection and testing of the earthing resistance is necessary to ensure that the system is still functioning correctly. Here are the benefits of a test link box:

- Simplifies Testing: Allows quick disconnection between down conductor and earthing for separate resistance testing.

- Enhances Safety: Provides a safe point to isolate the system during testing or maintenance.

- Compliance: Necessary for inspections required by IS/IEC 62305, IS 3043, and other national/international standards.

- Convenience: Offers easy access for electrical engineers or maintenance teams.

- Protects Infrastructure: Helps in early identification of faults in grounding systems.

How Is It Used in Testing?

One of the most important functions of the test link box is to enable earth resistance testing using tools like an Earth Resistance Tester or Clamp Meter. It also allows for easy measurement of earth resistance, which is crucial for ensuring the effectiveness of the connected lightning protection system components.

- Open the test link box and disconnect the link between the down conductor and the earth electrode.

- This isolates the earth electrode from the rest of the LPS.

- Connect your earth tester to the earth electrode and perform a fall-of-potential or clamp-on resistance test.

- Once the reading is taken, reconnect the test link to ensure the system remains protected.

A healthy earthing system should have resistance below 10 ohms (preferably <1 ohm for sensitive installations like data centers or hospitals).

Where Is the Test Link Box Installed?

The test link box is typically installed near the base of the structure, positioned close to the earth electrode to facilitate efficient testing and maintenance. It is commonly mounted on a wall or housed inside a weatherproof pit chamber with a protective lid to shield it from environmental elements. In some buildings, especially where accessibility and aesthetics are important, the test link box may also be placed inside a floor box or a dedicated earthing inspection chamber, allowing for convenient access during routine inspections and resistance testing.

Important: Its location should always be marked clearly and recorded in the building’s electrical schematic or safety log.

Types of Test Link Boxes & Their Uses

Test link boxes are widely used across various types of infrastructure equipped with lightning protection systems (LPS), including residential and commercial buildings, hospitals, schools, telecom towers, solar plants, wind farms, refineries, chemical plants, airports, and high-rise structures. Their inclusion is essential not only for facilitating earth resistance testing and maintenance but also for ensuring compliance with safety standards and regulations. Any facility with an LPS must incorporate test link boxes as a critical component to maintain system reliability and protect both equipment and occupants. Depending on the type of installation and conductor material, test link boxes come in different variants:

- Copper Test Link: A Copper Test Link Box is made from high-conductivity electrolytic copper and is typically used in systems with copper tapes or cables, offering excellent electrical performance.

- GI Test Link Box: The GI (Galvanized Iron) Test Link Box is made from galvanized iron and is a cost-effective option, widely used in standard lightning protection systems due to its affordability.

- SS Test Box: A Stainless Steel Test Link Box, constructed from stainless steel, provides superior corrosion resistance and is ideal for use in coastal areas or industrial environments where durability is essential.

- Polymer Box: A Polymer Test Link Box features a plastic enclosure and is best suited for indoor or dry locations; it is lightweight, insulated, and easy to install.

Installation Tips, Standards and Compliance

Proper installation of a test link box is essential to ensure the effectiveness and safety of a lightning protection system. It is vital to facilitate accurate earth resistance testing and maintain long-term reliability. Moreover, compliance with relevant national and international standards is critical for meeting safety regulations, avoiding system failures, and ensuring that the overall earthing and lightning protection setup performs as intended. Below are key installation tips and compliance guidelines every installer and engineer should follow.

- Ensure proper mechanical connection between the conductor and the earth electrode.

- Use anticorrosive paste or tapes when connecting copper to other metals.

- Install the box at an accessible height/location for regular testing.

- Label the test box clearly (e.g., “Lightning Test Link – Do Not Tamper”).

- Avoid direct exposure to water logging areas—use drainage or raised platforms if needed.

Standards and Compliance

- IS/IEC 62305 (Lightning Protection)

- IS 3043 (Earthing Practices)

- NBC India Part 8, Section 2 (Electrical Installations)

- IEEE 80 and IEEE 837

Without a test link box, regular testing becomes impractical and non-compliant with most building codes and safety audits.

When it comes to safeguarding your infrastructure from electrical faults and lightning strikes, don’t leave safety to chance — choose Adasearthlink, a name trusted by engineers, architects, and industries nationwide. We specialize in high-quality earthing systems, test link boxes, and lightning protection solutions that are engineered for performance, built to last, and fully compliant with international standards. Get in Touch Now!!

Conclusion

While small in size, the test link box is a critical component in the health and safety of a lightning protection system. It serves as a control point for inspection, maintenance, and verification of the system’s grounding efficiency. Installing one ensures that your structure is not just protected but also testable and compliant with modern electrical standards.

If you’re planning a new installation or upgrading your safety infrastructure, don’t overlook this tiny powerhouse—it could save your building from a catastrophic failure during the next thunderstorm.