In our everyday lives, we often overlook the intricate systems that work silently to keep us safe. One such unsung hero is earthing, also known as grounding. This process involves connecting the non-current carrying components of electrical systems (such as metallic frames) to the earth, ensuring that in the event of a fault, the current has a secure path to flow into the ground.

Among the various earthing methods available today, chemical earthing is becoming increasingly popular due to its reliability, low maintenance requirements, and its effectiveness in challenging soil conditions. This article will guide you through the concept of chemical earthing, its operational mechanism, its components, benefits, installation process, and its significance in our electrified world.

What Is Chemical Earthing?

Chemical earthing is a modern and growingly favored technique for grounding electrical systems. In contrast to conventional earthing methods that depend on salt and charcoal, chemical earthing employs uniquely engineered electrodes and conductive chemical substances to establish a low-resistance route for fault currents to flow into the ground. This approach offers improved safety, extended durability, and reduced maintenance.

The heart of chemical earthing is a GI (Galvanized Iron) or Copper rod filled or coated with conductive compounds. These rods are buried into the ground and connected to the electrical system. The surrounding chemicals ensure that resistance stays low and stable over time, even in rocky or dry soils where traditional methods often fail.

What is the main use of chemical earthing?

Chemical earthing serves the purpose of safely discharging excess or faulty electrical currents into the ground, thereby protecting individuals, equipment, and structures from electric shocks, short circuits, lightning strikes, and power surges.

In contrast to conventional earthing techniques, chemical earthing consistently maintains low resistance—even in dry or rocky soil—ensuring effective grounding throughout the year.

This method is particularly beneficial in areas with poor soil conductivity or where minimal maintenance is desired.

By offering a dependable and durable pathway for current to flow safely into the earth, chemical earthing improves electrical safety and minimizes the risk of damage to appliances, networks, and human life.

Specifications of Chemical Earthing

Key specifications for chemical earthing systems typically emphasize the electrode material, the chemical backfill compound, and the total resistance. Although specific requirements may differ according to local regulations and applications, the following are common aspects:

Electrode Material:

Copper Electrodes: Known for their high conductivity and resistance to corrosion, these are often favored for industrial applications and situations where longevity is essential.

GI (Galvanized Iron) Electrodes: An economical choice, suitable for residential and smaller-scale applications.

Copper Bonded Electrodes: Featuring a steel core encased in a copper layer (for example, a uniform thickness of 250 microns), these electrodes offer a good compromise between cost and performance

Earth Resistance:

A vital specification is the earth resistance, which should ideally be minimized, generally below 1 Ohm for effective chemical earthing. This guarantees a low-impedance route for fault currents.

Dimensions:

The size of electrodes varies according to current capacity and soil conditions. For example, a typical specification might include a 50mm diameter inner MS pipe with a 100mm diameter outer MS pipe, measuring 3000mm in length for higher current capacities.

Chemical Backfill Compound (Ground Enhancing Material – GEM/BFC):

Low Resistivity: The compound should exhibit very low resistivity, ideally below 0.2 Ohm-meter. This is commonly assessed by forming a 20cm cube of the material and measuring the resistance across its surfaces.

Moisture Retention: It should have excellent hygroscopic characteristics to absorb and hold moisture, ensuring reliable conductivity even during dry conditions. It should retain over 10% moisture at 105°C.

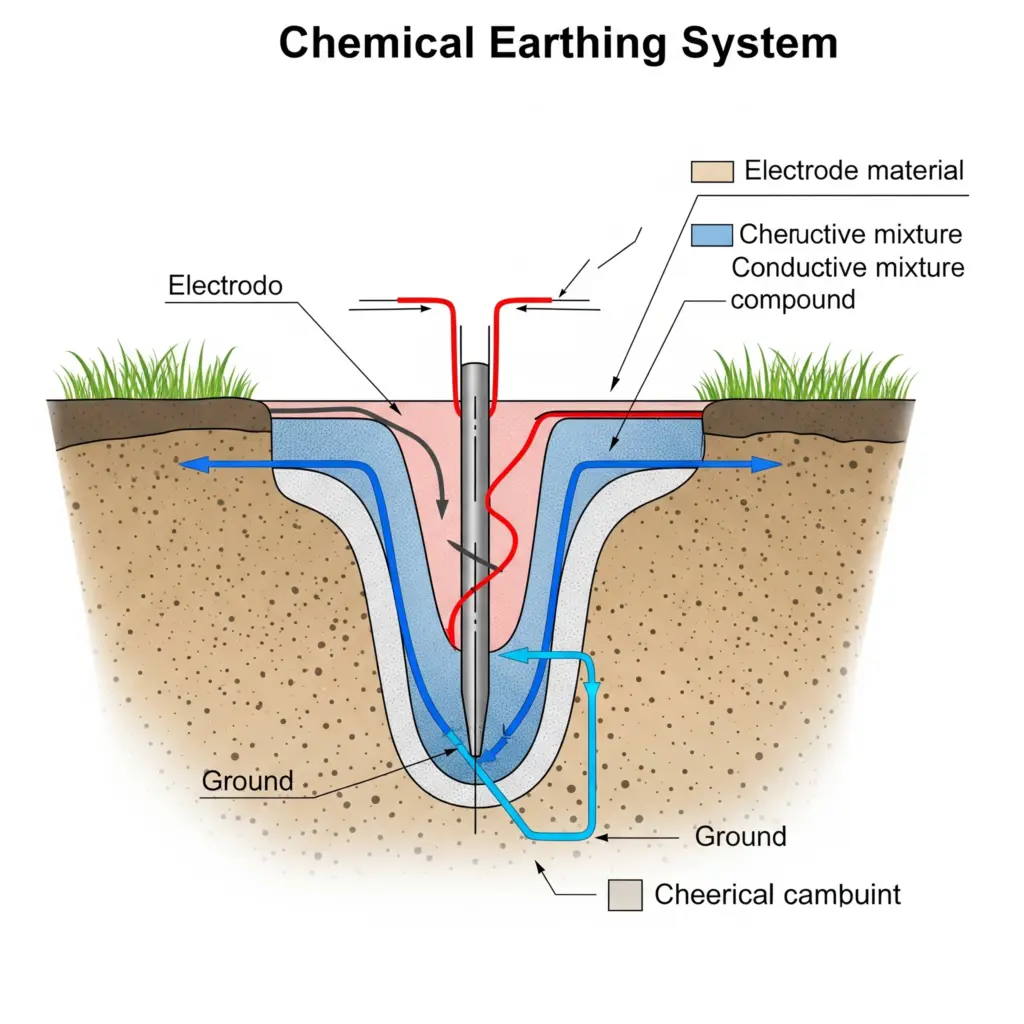

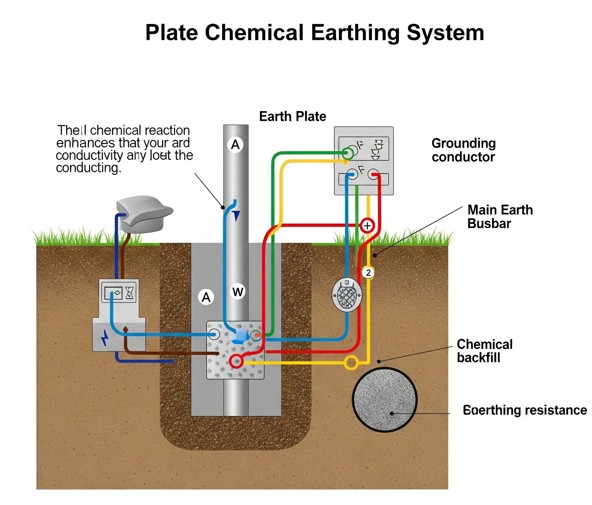

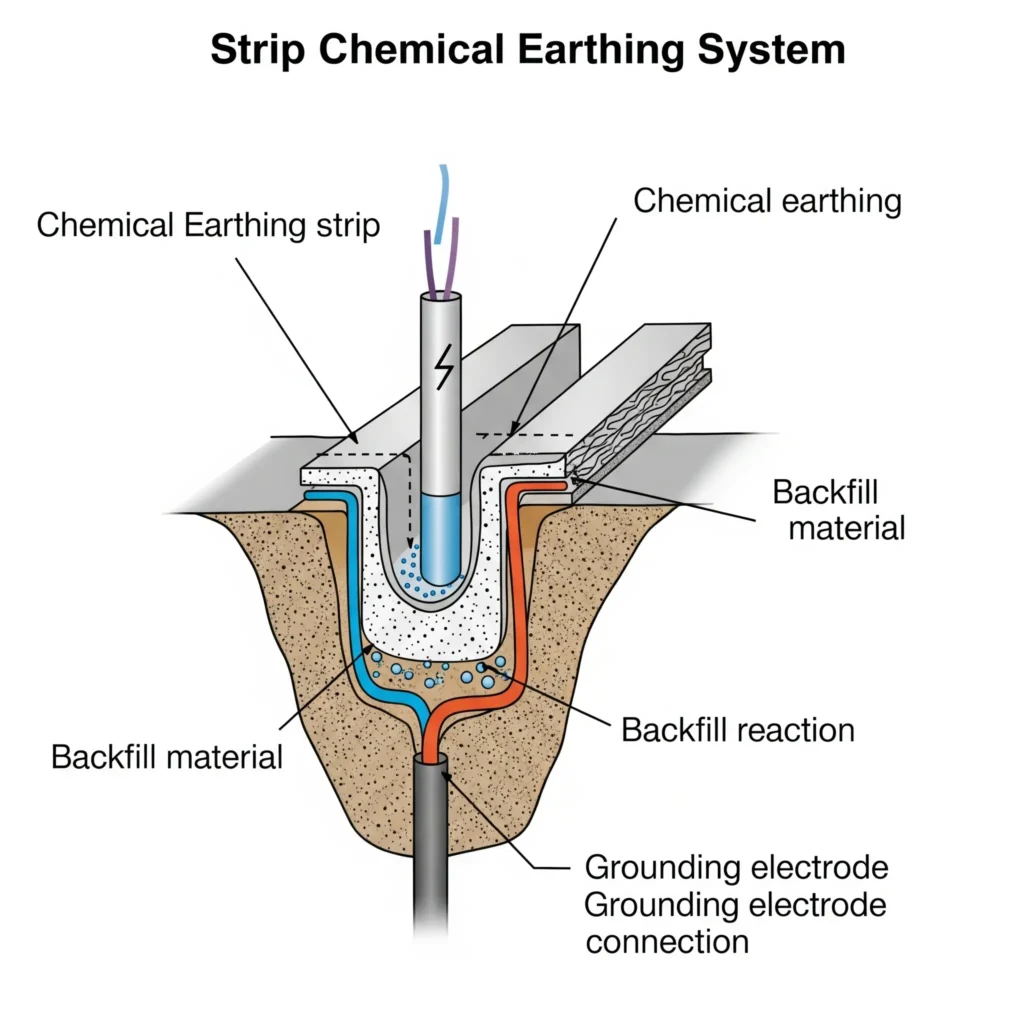

Diagram of a Chemical Earthing System

A standard chemical earthing system consists of the following elements:

- Earth Pit: A hole or pit excavated into the ground.

- Earthing Electrode: A copper or galvanized iron pipe, rod, or plate that is inserted vertically (or horizontally for plate or strip earthing) into the center of the pit.

- Chemical Backfill Compound (BFC/GEM): A highly conductive and moisture-retaining chemical mixture that is poured around the electrode within the earth pit. This compound effectively lowers soil resistivity and improves conductivity.

- Connecting Conductor: A low-resistance wire or strip (typically made of copper or GI) that links the earthing electrode to the electrical system or equipment being safeguarded.

- Earth Pit Cover/Inspection Chamber: A protective cover or chamber constructed over the earth pit for inspection and maintenance, although chemical earthing requires minimal upkeep.

- Watering Pipe (Optional/Less frequent in chemical earthing): While traditional earthing often necessitates a watering pipe for regular moisture replenishment, the BFC used in chemical earthing is formulated to retain moisture for extended periods, thereby decreasing the need for frequent watering.

Types of Chemical Earthing Systems

Chemical earthing systems are mainly classified based on the type of electrode utilized:

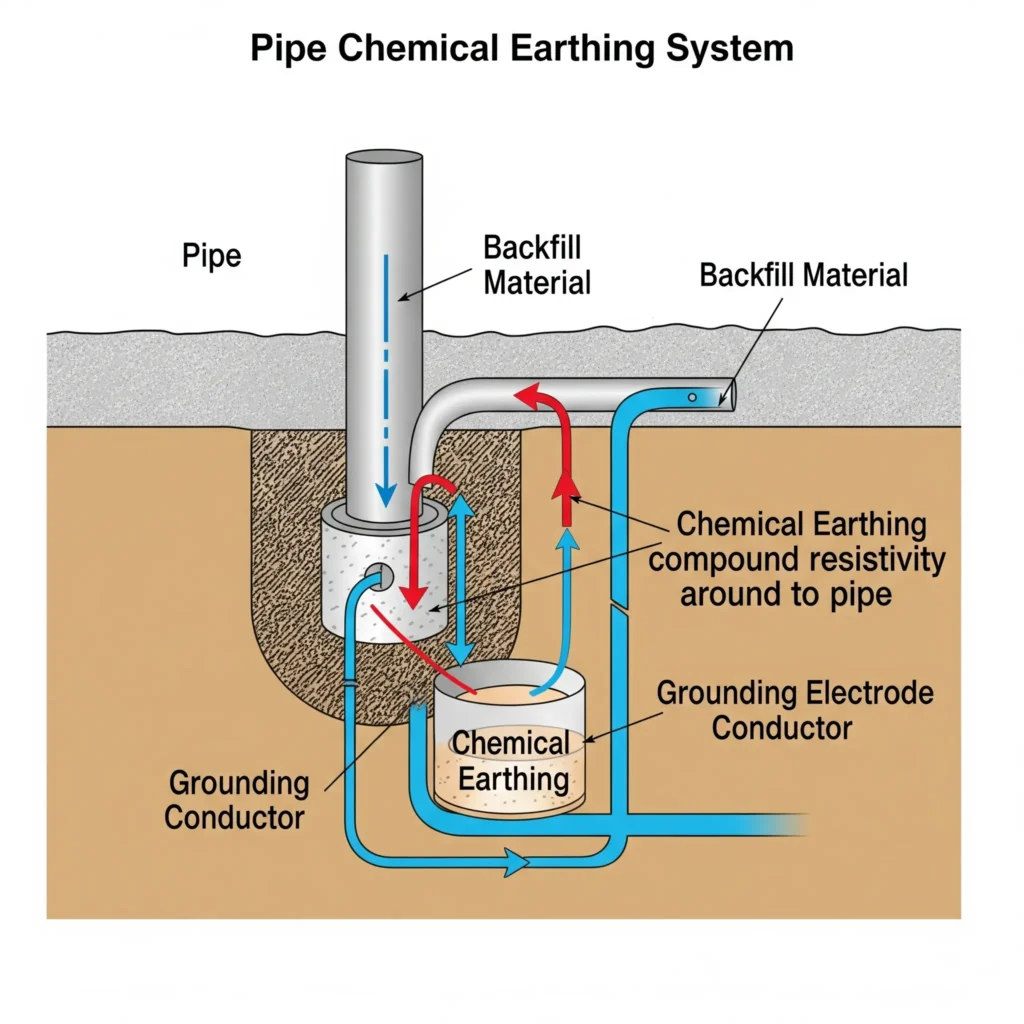

Pipe Earthing: This technique employs a galvanized iron (GI) or copper pipe as the electrode, which is generally buried vertically. The pipe is encased in a chemical compound (such as bentonite, graphite, and other minerals) to improve conductivity. It is frequently used in both residential and industrial settings, particularly in regions with high soil resistivity.

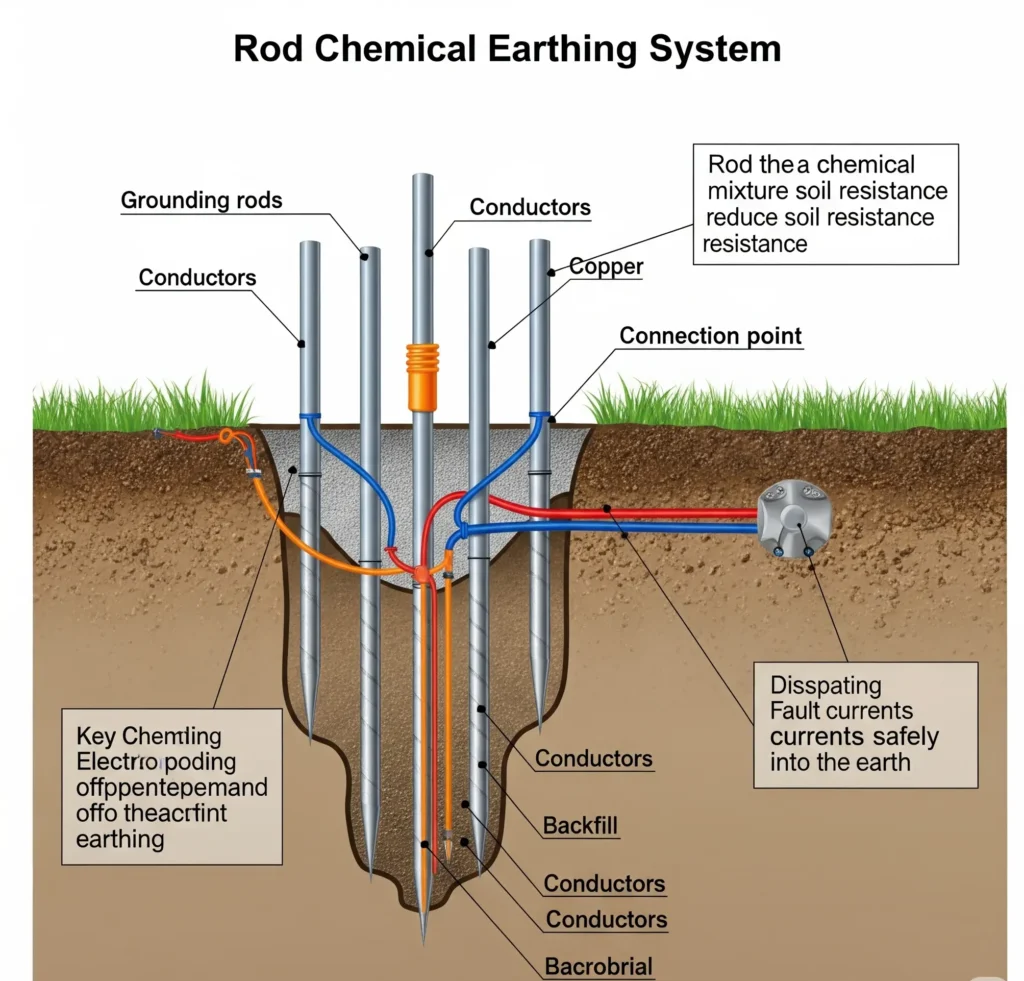

Rod Earthing: This method uses solid copper or GI rods that are driven deep into the ground, typically in a vertical orientation. Like pipe earthing, these rods are surrounded by a low-resistance chemical compound to sustain soil conductivity. Rod earthing is particularly suitable for rocky or sandy terrains where deep penetration is necessary.

Plate Earthing: This approach involves burying a thick copper or GI plate horizontally at a considerable depth (often exceeding 3 meters). The plate is enveloped by moisture-retaining chemical compounds to enhance conductivity. Plate earthing is particularly effective for high-voltage installations and substations due to its extensive surface area, which can manage high fault currents.

Strip (Wire) Earthing: This method consists of burying GI or copper strips or wires horizontally in trenches. Chemical compounds are used to boost soil conductivity around the strips, ensuring a dependable grounding system. This type is commonly employed in large industrial facilities and electrical transmission lines.

Copper-Bonded Earthing Electrodes: These electrodes feature a steel core that is reinforced with a pure copper layer. They provide excellent corrosion resistance and high conductivity, making them durable and appropriate for both commercial and residential applications that require long-lasting grounding.

GI Chemical Earthing Electrodes: Constructed from galvanized iron with a zinc coating, these electrodes are cost-effective and offer moderate electrical conductivity, making them suitable for a variety of environments.

Why is Chemical Earthing Better?

- Low Earth Resistance :Chemical compounds provide a reliable, low earth resistance, which is essential for the efficient dissipation of fault currents.

- Longer Lifespan: Electrodes made of copper or GI with anti-corrosive properties can endure for decades, significantly outlasting conventional salt-charcoal techniques.

- Low Maintenance :There is no requirement for regular watering or refilling, making it suitable for arid regions and remote setups.

- Environment Friendly :Using non-corrosive and non-toxic materials helps minimize soil contamination.

- Space Efficient: It necessitates smaller pits, making it perfect for contemporary buildings where space is at a premium.

Where is Chemical Earthing Used?

Chemical earthing is extensively utilized in various industries where dependable and low-maintenance grounding is vital. It is typically installed in residential properties, commercial buildings, industrial facilities, and IT centers to safeguard electrical systems and delicate equipment.

Furthermore, it plays a significant role in telecommunication towers, data centers, hospitals, and educational institutions, where consistent power supply and electrical safety are paramount.

Moreover, it is widely implemented in solar energy systems, wind farms, substations, and underground cabling networks, particularly in regions with high soil resistivity or arid climate conditions. Its versatility and effectiveness render it appropriate for nearly any setting that demands secure and stable earthing.

Conclusion on chemical earthing

Chemical earthing signifies a major improvement in grounding technology, providing a strong and dependable method for guaranteeing electrical safety and safeguarding delicate equipment.

The primary benefits of chemical earthing stem from its capacity to reliably sustain a very low earth resistance, regardless of varying soil conditions or during periods of drought. The hygroscopic properties of the chemical backfill material guarantee a constant moisture supply around the electrode, which is essential for optimal conductivity. As a result, this creates a stable and efficient grounding pathway for fault currents, greatly improving the safety of personnel and extending the lifespan of electrical systems.

In summary, chemical earthing offers a highly effective, dependable, and virtually maintenance-free grounding solution that is ideal for various applications, including residential and commercial structures, as well as essential industrial sites and power distribution systems. Its capacity to deliver stable, low-resistance grounding across diverse environmental conditions renders it a crucial element of contemporary electrical safety systems.