Lightning is one of nature’s most powerful and unpredictable forces. A single lightning strike can release millions of volts of electricity in a fraction of a second—posing a serious threat to buildings, electrical systems, and human life. While the air termination (lightning rods) and down conductors of a lightning protection system are critical in intercepting and directing this energy, the earthing system is what ultimately safely dissipates it into the ground.

In this article, we’ll explore why earthing is a fundamental component of any lightning protection system (LPS), how it works, and what makes it effective.

What Is Earthing in Lightning Protection?

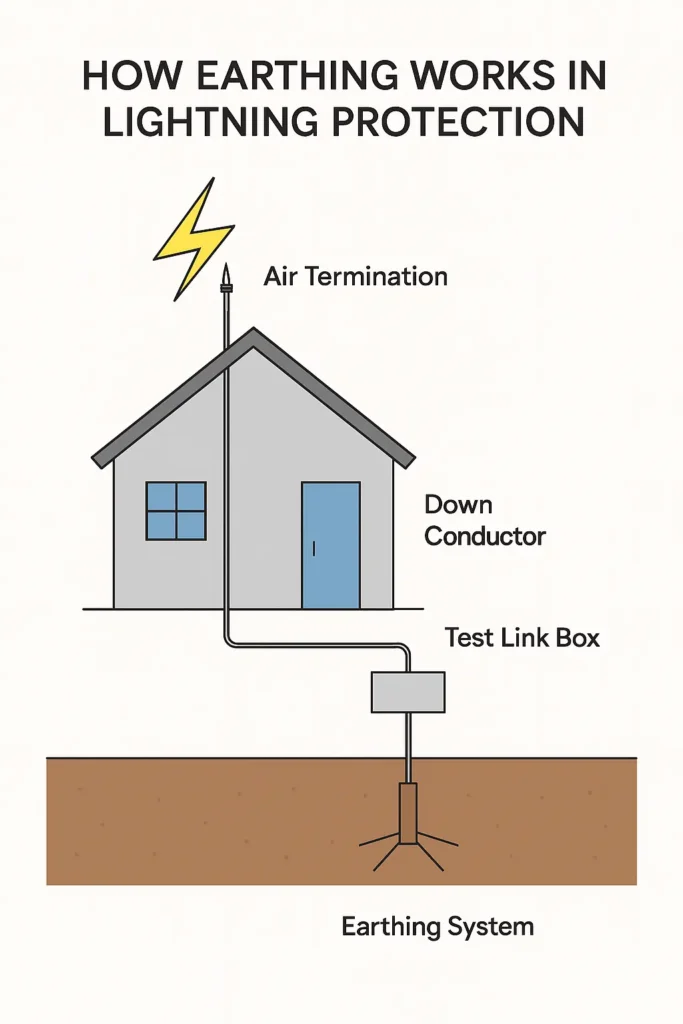

Earthing, also known as grounding, is the process of connecting parts of an electrical system (or in this case, a lightning protection system) to the earth through conductive paths, ensuring that any excess or fault current is safely diverted into the ground. In a lightning protection system, earthing ensures that the massive energy of a lightning strike is diverted away from people and equipment, does not build up dangerous voltages in the system, and safely returns to the earth without causing fires, explosions, or electrical failures. So what are the key components involved in it? Lets have a look at it: –

Components

1. Air Termination System: The Air Termination System is the first line of defense in a lightning protection system. It consists of lightning rods (also called air terminals), meshes, or conductor networks placed at the highest points of a building or structure. Its primary function is to intercept lightning strikes and safely capture the high-voltage energy before it can hit and damage the structure directly. By providing a preferred strike point, it significantly reduces the risk of fire, structural damage, or harm to occupants.

2. Down Conductor: The Down Conductor is a low-resistance path that carries the captured lightning current from the air termination system down to the ground. It is typically made of copper or aluminum and runs vertically along the exterior walls of a structure. Its function is to conduct the energy efficiently and safely, ensuring that the high-voltage surge does not pass through the building’s internal wiring or cause harm to equipment and people inside.

3. Test Link Box: The Test Link Box is a small, accessible interface point usually installed near the base of the down conductor, close to the earthing system. Its primary function is to allow disconnection of the down conductor from the earthing electrode for testing and maintenance. During inspections, technicians can use the test link box to measure earth resistance and ensure the system is functioning within safe parameters. It plays a vital role in ongoing system health and compliance.

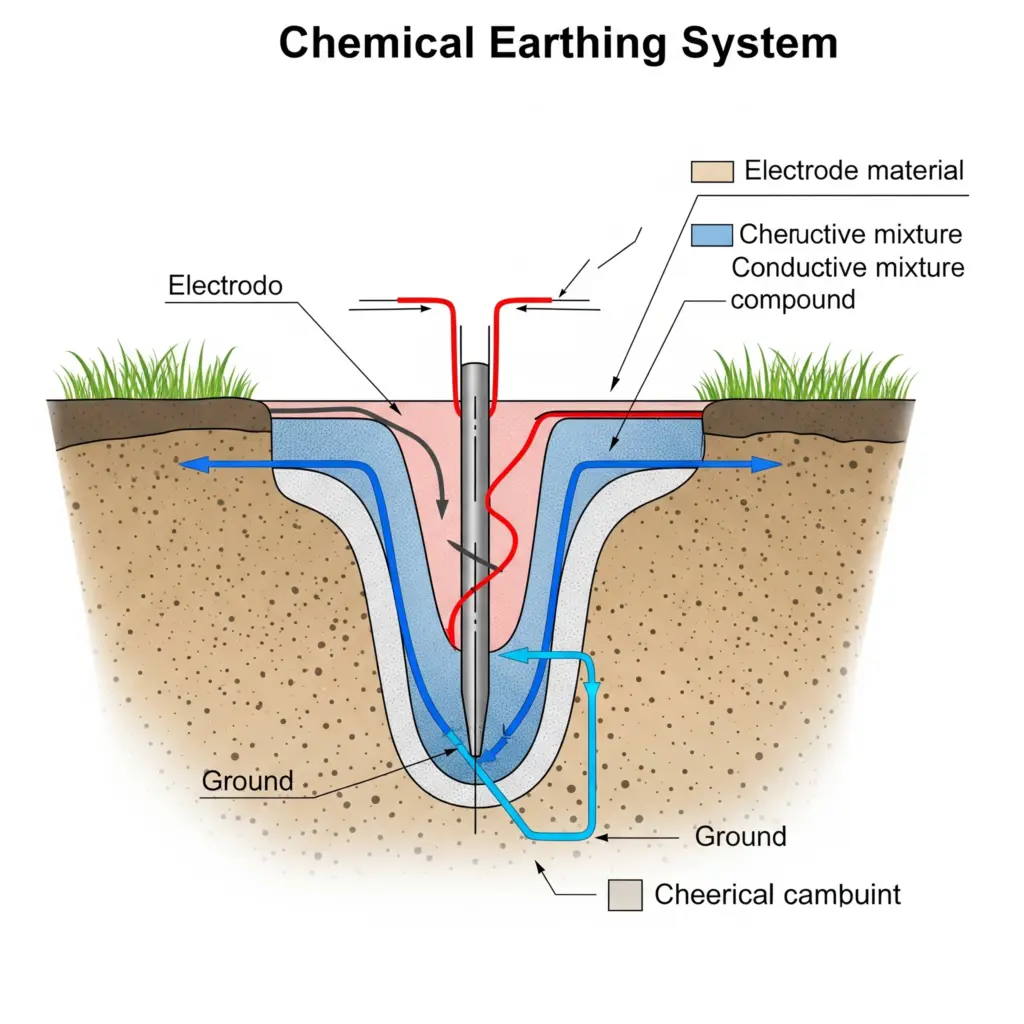

4. Earthing System: The Earthing System is the final and most critical component, responsible for dispersing the lightning current safely into the ground. It typically includes earth electrodes (rods, plates, or chemical earthing), conductors, and backfill compounds to lower soil resistance. A well-designed earthing system ensures that the high-energy current from a lightning strike is neutralized in the earth, preventing dangerous voltage buildup and protecting both infrastructure and human life.

Also, Get to Know What is Test Link Box & How does it Works?

How Earthing Works in Lightning Protection?

When lightning strikes a protected structure, a well-designed earthing system safely guides the massive electrical energy from the strike into the ground. Here’s how each component functions in this critical protection pathway:

- At the top of the structure, air terminals, commonly known as lightning rods, are strategically installed to attract lightning strikes. These are made of conductive materials such as copper or aluminum and are placed at the highest points of buildings or towers. Their primary function is to intercept the lightning strike before it hits any vulnerable part of the structure, providing a controlled entry point for the high-voltage discharge.

- Once the lightning is intercepted by the air terminal, the electrical current is immediately routed through down conductors. These are heavy-duty, low-resistance conductive cables that connect the air terminal to the earthing system at ground level. Down conductors are installed along the outer walls of the building and must be kept away from internal wiring and pipes to prevent side flashes or secondary damage. They carry the immense current — often exceeding 200,000 amperes — safely and efficiently downward.

- Before the current reaches the ground electrode, it passes through a test link box. This is a vital inspection and maintenance point in the lightning protection system. The test link box allows for routine testing of the continuity and effectiveness of the earthing system without having to dismantle any part of the installation. It provides a secure disconnect point for isolation during maintenance or resistance measurement of the earth electrode system.

- The last stage involves the current entering the earth termination system, which consists of earth electrodes such as copper rods, earthing plates, or chemical earthing setups. These are buried deep into the soil and serve to safely dissipate the lightning current into the ground, away from the structure. The effectiveness of this step depends on the soil resistivity, moisture content, and proper installation of the electrodes to ensure quick and complete discharge of energy.

This entire pathway must be highly conductive, corrosion-resistant, and continuous, or else the lightning current may find alternate destructive paths, like through plumbing, electrical wiring, or structural steel.

Why Is Earthing So Important in Lightning Protection?

Here are the few key points for which the earthing has vital role in safeguarding structures during lightning protection:-

1. Safe Dissipation of High Voltage

A proper earthing system ensures minimal resistance to current flow, helping disperse lightning safely. A typical lightning strike can carry 100 million to 1 billion volts and up to 200,000 amperes. Without a low-resistance earthing system, this energy can: travel into a building’s electrical network, cause fire hazards, damage electronic equipment or Electrocute occupants.

2. Voltage Equalization

During a lightning event, different parts of a building may have different electrical potentials (voltages). This difference can cause flashovers—where the current “jumps” between components.

Earthing helps to equalize potential across the structure, reducing the risk of dangerous voltage surges between metal parts or electrical equipment.

3. Protection of Electrical and Communication Equipment

Modern buildings rely on sensitive electronics—computers, networking systems, medical equipment, etc. A nearby lightning strike can induce transient voltages through cables or conductive paths, damaging this equipment. A well-designed earthing system acts as a path of least resistance, protecting: UPS systems, Data centers, Fire alarm systems and Surveillance and control panels.

4. Compliance with Safety Standards and Building Codes

Earthing is a legal and regulatory requirement in most countries. In India and many other regions, the following codes make earthing mandatory for LPS:

- IS/IEC 62305 (Protection Against Lightning)

- IS 3043 (Earthing Practice)

- NBC 2016 (National Building Code of India)

- IEEE 80, IEEE 837 (USA)

5. Repeatability and Maintenance

Proper earthing enables regular testing through a Test Link Box, As electrical engineers can: Measure earth resistance (typically <10 ohms, ideal <1 ohm), Identify corrosion or deterioration in earth conductors and Plan corrective measures like salt/charcoal treatments or additional earth pits.

What are the Consequences of Poor Earthing?

Failing to implement an effective earthing system can lead to several serious risks for both human safety and infrastructure. Some of the key consequences include:

- Building Fires due to high-current discharge.

- Equipment Burnout even without a direct strike (due to induced surges).

- Electric Shock Hazards to occupants and maintenance personnel.

- Loss of Communication & Data due to surge failures.

- Higher Insurance Premiums or Denied Coverage.

- Non-compliance Penalties under building and electrical codes.

Characteristics of a Good Earthing System

A reliable earthing system for lightning protection should:

- Low Resistance: Ideally below 1 ohm, and definitely maintained under 10 ohms for effective dissipation.

- High Conductivity: Use of conductive materials like copper, galvanized iron (GI), or copper-bonded rods to ensure efficient current flow.

- Corrosion Resistance: Components should be protected against moisture, soil acidity, and chemical corrosion to ensure long-term reliability.

- Accessibility: The earthing system should be easily testable via a Test Link Box or inspection chamber for maintenance and compliance.

- Redundancy: Incorporating multiple earth electrodes or an earthing mesh/grid to improve system reliability and reduce failure risk.

Earthing in Special Installations

Different types of facilities have unique earthing requirements based on their sensitivity, function, and risk exposure. Let’s look at how earthing is implemented in some critical installations:

1. Hospitals & Data Centers

These are highly sensitive environments where even minor electrical disturbances can disrupt critical operations or compromise patient and data safety. Therefore, they require very low earth resistance, often below 1 ohm, to ensure stable electrical grounding. Additionally, isolated or dedicated earthing systems are used to separate sensitive medical or IT equipment from general power circuits, reducing the risk of interference or shock.

2. Industrial Plants

Industrial settings typically involve heavy machinery, large motors, and high transient currents during operations or faults. To handle this load, a robust earth mesh or grid earthing system is installed across the plant. This ensures uniform potential across large areas and helps in effective dissipation of fault and lightning currents without creating step or touch voltage hazards.

3. Telecom Towers

Telecommunication installations are often exposed to lightning strikes due to their height and require well-coordinated grounding systems. The earthing design must integrate both the lightning protection system (LPS) earthing and the signal/reference grounding used by communication equipment. Poor coordination can lead to equipment malfunction, signal noise, or surge damage.

4. Solar PV Systems

Solar power systems face unique risks from lightning, switching surges, and DC current faults. Earthing in these setups must ensure both AC and DC side protection, particularly for inverters and panels. A well-coordinated system involving surge protection devices (SPDs) and proper earthing ensures that fault currents or lightning surges are safely diverted, protecting the PV modules and enhancing system reliability.

When it comes to safeguarding your infrastructure from electrical faults and lightning strikes, don’t leave safety to chance — choose Adasearthlink, a name trusted by engineers, architects, and industries nationwide. We specialize in high-quality earthing systems, test link boxes, and lightning protection solutions that are engineered for performance, built to last, and fully compliant with international standards. Get in Touch Now!!

Conclusion

In any lightning protection system, earthing is foundational that cannot be skipped at any cost. Without a proper grounding system, the energy intercepted by rods and conductors has nowhere safe to go. That makes the system incomplete and dangerous.

If you’re planning a lightning protection system, never cut corners on earthing—it’s the final and most critical line of defense between your building and a bolt from the sky.