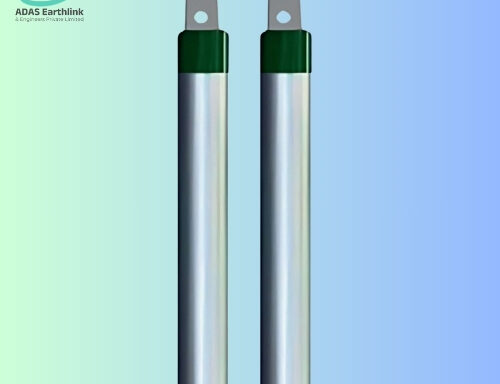

Copper Bonded Earthing Electrode

Our Copper Bonded Earthing Electrode is a high-performance grounding solution featuring a steel core uniformly bonded with a layer of pure copper. This combination ensures excellent conductivity, corrosion resistance, and mechanical strength.

Present in different variant 50 mm , 60 mm , 80mm etc .

| Products Price | ₹1,800.00 | ||

Click to add this item to cart. | |||

Products Description

| Product Model | Diameter of Electrode (mm) | Length of Electrode (meter) | Connection Terminal (mm) | Inner Strip Size (mm) |

|---|---|---|---|---|

| ADAS/CBEE/48 | 48 | 1, 2 & 3 | 32x6x100 | 25×3 |

| ADAS/CBEE/58 | 58 | 1, 2 & 3 | 40x6x100 | 25×6 |

| ADAS/CBEE/76 | 76 | 1, 2 & 3 | 50x6x100 | 25×6 |

| ADAS/CBEE/88 | 88 | 1, 2 & 3 | 50x6x100 | 25×6 |

Designed to provide stable grounding in diverse soil conditions, this electrode is a durable, maintenance-free, and economical solution for commercial, industrial, and utility-scale electrical installations. It ensures effective dissipation of fault currents and meets national and international standards, including IS 3043.

Ideal for power distribution networks, telecom towers, substations, and renewable energy systems, it is a popular choice for reliable and long-lasting earthing.

It features a low-carbon steel core coated with 99.9% pure copper through an electrolytic process, ensuring high conductivity, mechanical strength, and corrosion resistance.

Key Features:-

- Excellent Conductivity: Pure copper coating ensures efficient current dissipation.

- Corrosion Resistance: Electrolytically bonded copper layer protects against rust and degradation.

- High Mechanical Strength: Steel core provides rigidity and resistance to bending or breaking.

- IS 3043 Compliant: Adheres to Indian standards for safe and reliable grounding.

- Cost-Effective Alternative: Offers performance close to pure copper at a lower cost.

- Broad Applications: Used in power plants, industries, commercial buildings, and telecom.

How it works:

The purpose of a copper-bonded earthing electrode is to provide a low-resistance path for fault currents, lightning strikes, and static charges to safely dissipate into the earth.

Copper has great electrical conductivity, second only to silver. The copper coating on the electrode guarantees that electrical currents are efficiently transferred from the earthing conductor to the surrounding soil.

Corrosion Resistance: Copper is highly resistant to corrosion in a variety of soil conditions, including aggressive and damp ones. In some extreme situations, this considerably increases the electrode’s lifespan when compared to untreated steel or even galvanized iron.

Mechanical Strength: The steel core provides the required tensile strength and rigidity, allowing the electrode to be driven deeply into the ground without bending or breaking, even in hard or rocky terrain.

Fault Current Dissipation: When an electrical system experiences an overcurrent or surge (for example, caused by a fault or a lightning strike), the current flows via the earthing conductor to the copper-bonded electrode. The electrode, with its low resistance and vast surface area (particularly when paired with EEM), efficiently disperses this energy into the ground, minimizing equipment damage, lowering fire threats, and protecting people from electric shock.

Manufacturing Process (Key Aspects):

The molecular bonding process is critical to the quality of a copper-bonded electrode:

Steel Core Preparation: To achieve proper adhesion, steel rods with high strength and low carbon content are produced and cleaned.

Electrolytic Bonding: The steel rod is immersed in an electrolytic solution that contains copper ions. An electroplating technique deposits a homogeneous, thick layer of pure copper (usually 100 to 250 microns or more, depending on specification) onto the steel surface. This forms a strong, molecular link between the two metals, which prevents separation.

Quality Control: Strict quality control measures are used, such as adhesion tests (e.g., bend tests to verify the copper coating does not break or peel), coating thickness testing, and corrosion resistance tests.

Finishing: The rods can be pointed at one end for simpler driving and threaded at the other to link extendable pieces using couplers.

Products Features

| Type | |

| Thickness | 3mm |

| Grade | Pure copper |

Review Copper Bonded Earthing Electrode.